In the world of manufacturing, precision, efficiency, and innovation are paramount. One technology that has transformed the landscape of manufacturing is Computer Numerical Control (CNC) machining. In this comprehensive guide, we'll delve into the intricacies of the CNC machining process, explore its functions, and discern the disparities between CNC machining and traditional methods.

Understanding CNC Machining

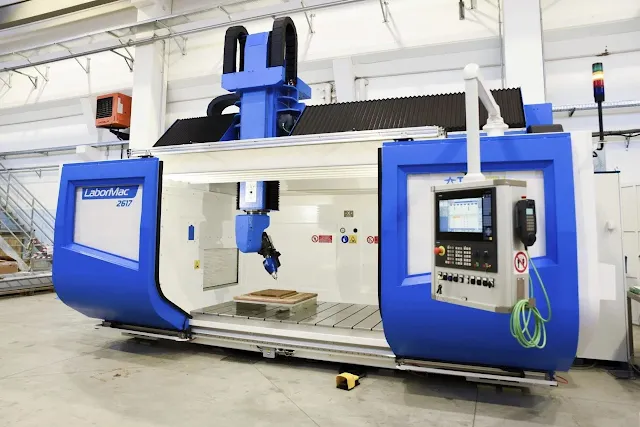

CNC machining is a cutting-edge manufacturing process that

utilizes computerized controls to operate and manipulate machine tools. These

machines, guided by pre-programmed instructions, precisely execute a variety of

tasks, ranging from cutting and drilling to milling and shaping, with

unparalleled accuracy and repeatability.

Functions of CNC Machines

CNC machines are versatile tools capable of performing a

multitude of operations, including:

Milling: CNC milling machines employ rotating cutting tools to remove material

from a workpiece, producing intricate shapes and designs.

Turning: CNC turning lathes rotate a workpiece while a cutting tool removes

material, enabling the creation of cylindrical components like shafts and rods.

Drilling: CNC drilling machines bore precise holes into workpieces, ensuring

uniformity and accuracy across multiple parts.

Grinding: CNC grinding machines utilize abrasive wheels to refine the surface

finish of workpieces, achieving tight tolerances and smooth textures.

Routing: CNC routers carve intricate patterns and contours into materials such as

wood, plastic, and metal, ideal for prototyping and artistic applications.

CNC Machining vs. Traditional Machining

While both CNC machining and traditional machining methods

serve the purpose of shaping raw materials into finished products, they differ

significantly in terms of operation, precision, and efficiency.

Precision and Accuracy

CNC machining offers unparalleled precision, as it relies on

digital instructions to guide the machining process, minimizing human error and

ensuring consistent results. Traditional machining, on the other hand, is more

reliant on the skill and experience of the operator, making it susceptible to

deviations and inaccuracies.

Automation and Efficiency

One of the most significant advantages of CNC machining is

its automation capabilities. Once programmed, CNC machines can operate

autonomously, executing complex tasks with minimal human intervention.

Traditional machining, conversely, often requires manual operation and constant

supervision, leading to slower production rates and increased labor costs.

Flexibility and Complexity

CNC machining excels in handling intricate designs and complex geometries with ease, thanks to its advanced programming capabilities. Traditional machining techniques, while proficient in basic operations, may struggle to replicate the same level of intricacy and precision.

Conclusion

In conclusion, CNC machining stands as a testament to the

relentless pursuit of innovation in the manufacturing industry. With its

unmatched precision, efficiency, and versatility, CNC technology continues to

revolutionize the way we approach production processes, driving advancements

across various sectors.

FAQs

What materials can be used with CNC machining?

CNC machining can work with a wide range of materials,

including metals like aluminum, steel, and titanium, as well as plastics, wood,

and composites.

Is CNC machining suitable for prototyping?

Absolutely! CNC machining offers rapid prototyping

capabilities, allowing designers to quickly iterate and refine their designs

before moving to full-scale production.

How long does it take to program a CNC machine?

The time required to program a CNC machine varies depending

on the complexity of the part and the proficiency of the programmer. Simple

parts may take minutes to program, while more intricate designs could take

several hours.

Can CNC machines perform 3D machining?

Yes, many CNC machines are equipped with multi-axis

capabilities, enabling them to perform intricate 3D machining operations with

precision and accuracy.

Are CNC machines cost-effective for small-scale production?

While the initial investment in CNC machinery may be higher

compared to traditional equipment, the long-term cost savings in terms of

labor, material wastage, and productivity often make CNC machining a

cost-effective solution for small-scale production runs.

0 Comments